The choice between a jacket and coils is based on a number of considerations. For highly corrosive or highly reactive materials, a jacket has the advantage that there are no extra materials of construction and no extra metal surface in contact with the process other than the normal vessel wall. There is also less risk of cooling fluid coming into contact with the reaction mass. For the manufacture of pharmaceuticals, fine chemicals and performance products, a jacket minimizes contamination as there are no extra surfaces to clean. For materials with difficult rheology the full range of agitator designs can be used with a jacket without difficulty. However, a jacket has a lower heat transfer performance than a coil as there will be a lower process side coefficient, usually a greater wall thickness, and a smaller surface area.

A jacket may also require a higher service side flow. For exothermic reactions, a jacketed vessel has the disadvantage that the area/volume ratio decreases with increasing scale. The use of a greater height/diameter ratio at larger scale can help to reduce this problem, but only to a limited extent. A coil has the advantage that a large surface area can be provided, for example, in one particular highly exothermic reaction 18 m2m−3 has been installed in a 5 m3 reactor. However, it is important not to pack the coil so tightly as to form a false wall.

The constant flux jacket has very fast temperature control response due to the short length of the flow channels and high velocity of the heat transfer fluid. Like the half coil jacket the heating/cooling flux is uniform. Because the jacket operates at substantially constant temperature however the inlet temperature oscillations seen in other jackets are absent. An unusual feature of this type jacket is that process heat can be measured very sensitively.

This allows the user to monitor the rate of reaction for detecting end points, controlling addition rates, controlling crystallization etc. It can be argued that heat transfer coefficient is also an important parameter. It has to be recognized however that large batch reactors with external cooling jackets have severe heat transfer constraints by virtue of design. It is difficult to achieve better than 100 Watts/litre even with ideal heat transfer conditions. By contrast, continuous reactors can deliver cooling capacities in excess of 10,000 W/litre. For processes with very high heat loads, there are better solutions than batch reactors.

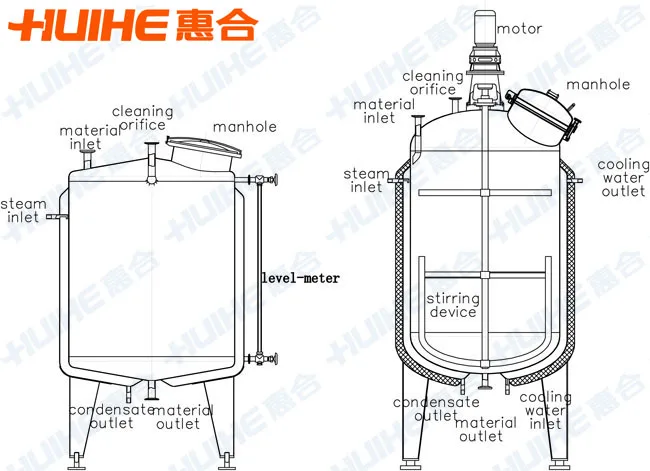

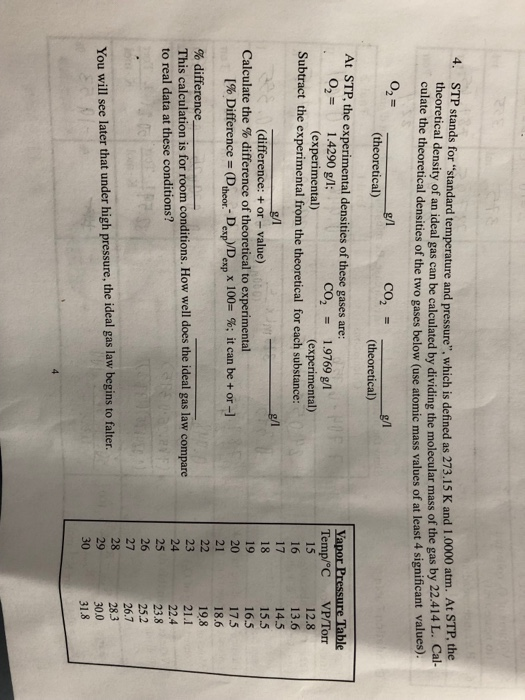

Products within batch reactors usually liberate or absorb heat during processing. Even the action of stirring stored liquids generates heat. In order to hold the reactor contents at the desired temperature, heat has to be added or removed by a cooling jacket or cooling pipe. Heating/cooling coils or external jackets are used for heating and cooling batch reactors. Heat transfer fluid passes through the jacket or coils to add or remove heat. The single jacket is probably the oldest design of external cooling jacket.

Despite being a tried and tested solution, it has some limitations. On large vessels, it can take many minutes to adjust the temperature of the fluid in the cooling jacket. The distribution of heat transfer fluid is also far from ideal and the heating or cooling tends to vary between the side walls and bottom dish. Another issue to consider is the inlet temperature of the heat transfer fluid which can oscillate over a wide temperature range to cause hot or cold spots at the jacket inlet points. The coil has been sized on mean heat transfer values.

However, it may be better to size the control valve to supply the maximum (start-up) load. With large coils in tanks, this will help to maintain a degree of steam pressure throughout the length of the coil when the steam is turned on, helping to push condensate through the coil to the steam trapping device. If the control valve were sized on mean values, steam pressure in the coil at start-up will tend to be lower and the coil may flood. The half coil jacket is made by welding a half pipe around the outside of the vessel to create a semi circular flow channel.

The heat transfer fluid passes through the channel in a plug flow fashion. A large reactor may use several coils to deliver the heat transfer fluid. Like the single jacket, the temperature in the jacket is regulated to control heating or cooling. The constant flux cooling jacket is a relatively recent development.

It is not a single jacket but has a series of 20 or more small jacket elements. The temperature control valve operates by opening and closing these channels as required. By varying the heat transfer area in this way, the process temperature can be regulated without altering the jacket temperature. The plug flow characteristics of a half coil jacket permits faster displacement of the heat transfer fluid in the jacket . It also provides good distribution of heat transfer fluid which avoids the problems of non uniform heating or cooling between the side walls and bottom dish.

Like the single jacket design however the inlet heat transfer fluid is also vulnerable to large oscillations in temperature. The result is an increased conversion of reactant feed to product. Despite significant improvements in agitator blade and baffle design, mixing in large batch reactors is ultimately constrained by the amount of energy that can be applied. On large vessels, mixing energies of more than 5 Watts per litre can put an unacceptable burden on the cooling system. High agitator loads can also create shaft stability problems.

Where mixing is a critical parameter, the batch reactor is not the ideal solution. Much higher mixing rates can be achieved by using smaller flowing systems with high speed agitators, ultrasonic mixing or static mixers. The batch reactor is the generic term for a type of vessel widely used in the process industries. In some cases, they are not referred to as reactors but have a name which reflects the role they perform .

The Wilson plot technique enables a deeper investigation of overall heat transfer coefficients, with very limited additional effort, if certain prerequisites are fulfilled. For stirred tank bioreactors, the required exponential relation between characteristic velocities and their corresponding heat transfer coefficients are available and thus, accessible for this approach. Strictly, the Wilson plot method only is valid for fully established turbulent flow. Further, for heat transfer with phase change, the thermal resistances of both sides cannot be considered independent and thus, further mathematical modifications are needed.

For further reading, the review of Fernández-Seara, et al. is recommended. Like the heat exchanger and gravity drained tanks case studies, the jacketed stirred reactor is a self regulating processes. That is, the measured process variable naturally seeks a steady operating level if the controller output and major disturbance are held constant for a sufficient length of time. A typical batch reactor consists of a storage tank with an agitator and integral heating/cooling system. These vessels may vary in size from less than 1 litre to more than 15,000 litres.

They are usually fabricated in steel, stainless steel, glass-lined steel, glass or exotic alloy. Liquids and solids are usually charged via connections in the top cover of the reactor. Vapors and gases also discharge through connections in the top. As defined here generally represent a conjugate heat transfer process between two fluids through a wall. If such values are determined experimentally it might be desirable to deeper investigate the underlying processes.

One example might be the presence of a one-sided limitation, significantly reducing the overall heat transfer capabilities. Due to its nature, the overall heat transfer is limited by its least capable contributor, acting as insulation. Therefore, investigations targeting one sided heat transfer coefficients would require the other side to have infinite heat transfer capabilities. This would enable the direct calculation of the desired heat transfer coefficient.

Although such results might have limited universality, studies in adequate models can simplify further scale-up. To stop the upward spiral of hotter temperatures increasing the rate of reaction that produces even more heat, the vessel is enclosed with a jacket . A cooling liquid flows through the jacket, collecting heat energy from the outer surface of the reactor vessel and carrying it away as the cooling liquid exits at the jacket outlet. Where α and αs are the process and service side heat transfer coefficients, respectively. The service side fouling resistance, l/αf, will be available from local experience or from Kern , for example.

As a general guide, approximate overall coefficients typical of agitated jacketed vessels are given in Tables 1 and 2. When the flow of cooling liquid through the jacket increases, more heat is removed. This lowers the reactor temperature, slowing the rate of the reaction, and thus decreasing the amount of feed converted to product during passage through the reactor.

And like the heat exchanger and the gravity drained tanks, the jacketed stirred reactor process is actually a sophisticated simulation derived from first-principles theory and available in commercial software. Nevertheless, the methods and procedures we establish during these investigations are directly applicable to a broad range of industrial processes with streams comprised of liquids, gases, powders, slurries and melts. The single jacket design consists of an outer jacket which surrounds the vessel.

Heat transfer fluid flows around the jacket and is injected at high velocity via nozzles. The temperature in the jacket is regulated to control heating or cooling. However, with heat exchangers not designed to cope with the effects of waterlogging, this can lead to corrosion of the heating surface, inevitably reducing the service life of the exchanger.

Cold air at 4 °C flowing at 3 m/s can soon freeze condensate locked in the coils, resulting in premature and unwarranted failure. Proper drainage of condensate is essential to maintain the service life of any heat exchanger and air heater. For heat exchangers, any unwanted reduction in the heating surface area, such as that caused by condensate backing up into the steam space, can affect the flow of heat through the heating surface. This can cause the control system to become erratic and unstable, and processes requiring stable or accurate control can suffer with poor performance. However, further along the length of the coil the steam velocity may be lower, and the coil may be running partially full of water.

In very long coils, such as those sometimes found in seagoing tankers or in large bulk storage tanks, a significant pressure drop occurs along the length of the coil. To achieve the mean coil temperature, an average steam pressure of approximately 75% of the inlet pressure may be used. In extreme cases the average pressure used may be as low as 40% of the inlet pressure. Estimates overall heat transfer coefficient for a vessel with an agitator along with heating/cooling medium flowing in jacket, jacket with spiral or half pipe coil. Because the reactor has a constant residence time, the amount of heat energy released inside the vessel is directly related to the percent of feed converted to product. By controlling the temperature in the reactor, we can maintain the percent conversion to the desired value.

The chemical reaction releases heat and this energy causes the temperature of the material in the vessel to rise. As temperature rises, the conversion of feed to product proceeds faster, leading to the release of even more heat. The design and layout of the steam coil will depend on the process fluid being heated. This will ensure that there are no weak points in the tank lining, where there is a risk of leakage of corrosive liquids. In these cases the coil itself may also be made of corrosion resistant material such as lead covered steel or copper, or alloys such as titanium. The major disturbance in this jacketed stirred reactor is the result of an unfortunate design.

Specifically, the temperature of the cooling liquid entering the jacket changes over time . As labeled in the figure , a reactant feed stream enters the top of the vessel. A chemical reaction converts most of this feed into the desired product as the material passes through what is essentially a stirred tank.

How To Calculate Minimum Stirrable Volume The stream exiting the bottom of the vessel includes the newly created product plus that portion of the feed that did not convert while in the vessel. If the steam trap is only sized on the first condition, it is possible that it may not pass the stall load . To calculate the heat transfer area, a value for the overall heat transfer coefficient, U, must be chosen. This will vary considerably with the thermal and transport properties of both fluids and a range of other conditions.

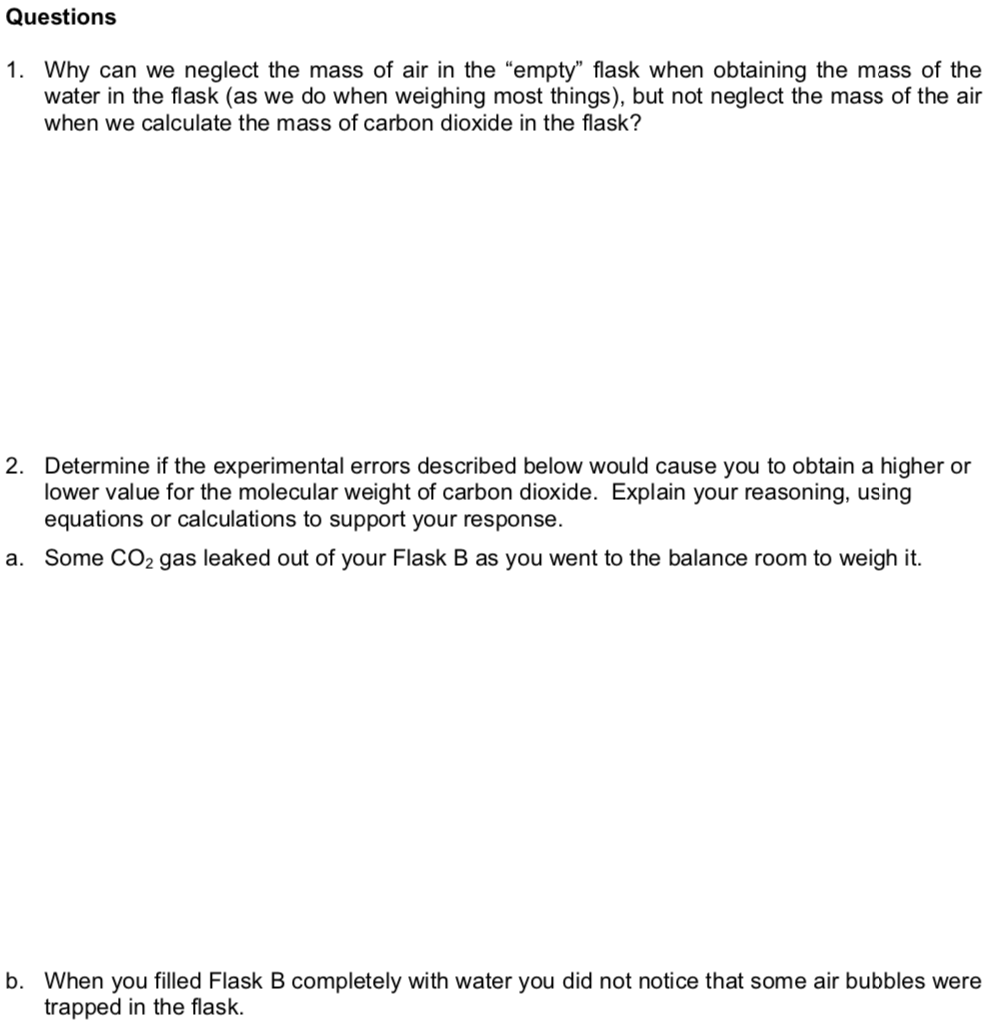

Indirect heating of fluids is covered in this tutorial including layouts, control and drainage of coils and jackets, and heat transfer calculations. If it is desired that the heat transfer area must be provided as a jacket only. What changes in process design if any would you carry out?

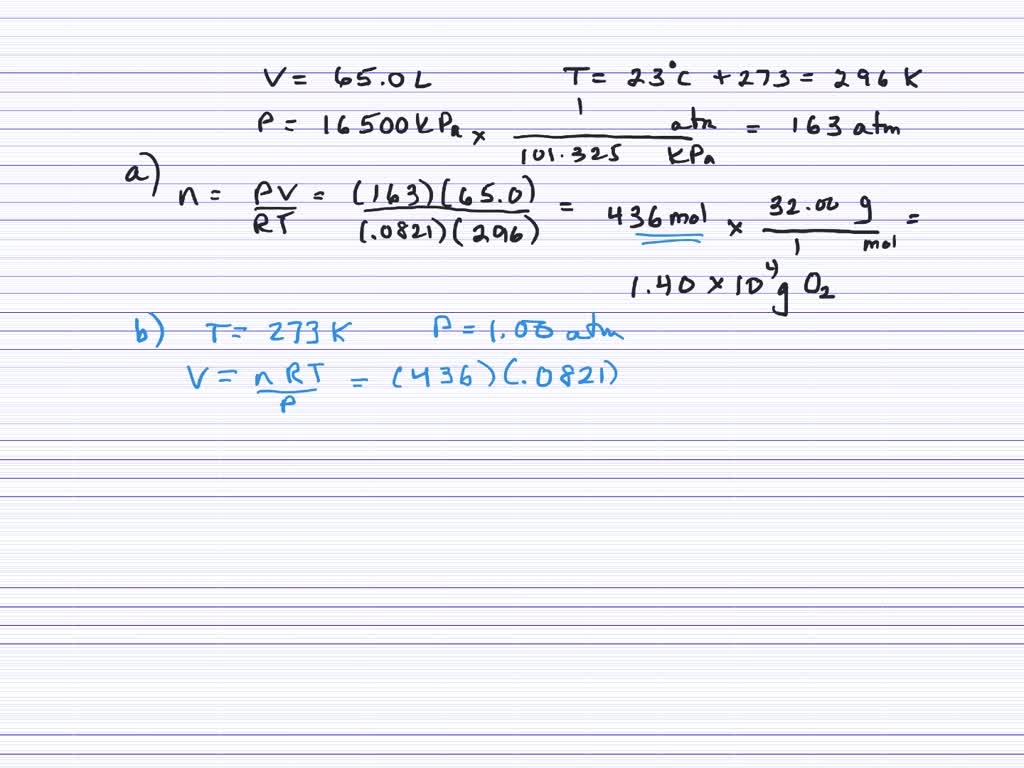

Show one set of calculation to illustrate your procedure. Example of a Wilson plot applied to a jacketed stirred tank reactor with the aim to determine the jacket side heat transfer coefficient by varying the stirring frequency. Critical pressure drop will occur across the control valve during start-up, therefore the minimum steam pressure in the heating coil should be taken as 58% of upstream absolute pressure. On the product side of the coil a thermal boundary layer will exist in which there is a temperature gradient between the surface and the bulk fluid. If this temperature difference is relatively large, then the natural convective currents will be significant and the heat transfer coefficient will be high.

These are stationary blades which break up flow caused by the rotating agitator. These may be fixed to the vessel cover or mounted on the interior of the side walls. Further, the intercept represents the extrapolated point, where the process side thermal resistance approximates zero, representing a consistent graphical interpretation of the plot. However, the chart also shows that equidistant spacing of stirring frequencies during experimental determination might lead to unfavorable mathematical weighing of settings that show lower measurement accuracy. For example, in a tubular heat exchanger, higher fluid flow velocities often go along with lower measurable temperature differences and thus, are more impacted by noise.

As the temperature of the cooling liquid entering the jacket changes, so does its ability to remove heat energy. Warm liquid removes less energy than cool liquid when flowing through the jacket at the same rate. As shown in the figure below , the flow rate of cooling liquid is adjusted with a valve on the cooling jacket outlet stream. The conductivity of the wall material can be found in standard texts [Kern, ]. The resistance may be significant for some vessels linings, for example, glass lined steel, where the manufacturer's data should be consulted. There will also be some limitations on the ability of glass lining to withstand thermal shock.

If heat exchangers are oversized, sufficient heating surface may remain when condensate backs up into the steam space, and reduction of thermal performance may not always occur. If one valve is to be used, this valve must ensure the maximum heat load is catered for, while maintaining the required steam pressure in the coil to assist the drainage of condensate from it at start-up. However, for reasons previously explained, two valves may be better. Maximum heat transfer will occur when the temperature difference between the steam and the process fluid is at its maximum, and should take into consideration the extra pipe area allowed for fouling. Tank coils are also extensively used in electroplating and metal treatment. Electroplating involves passing articles through several process tanks so that metallic coatings can be deposited on to their surfaces.

Submerged steam coils - A widely used form of heat transfer involves the installation inside a tank of a steam coil immersed in a process fluid. Will this calculation be applicable for agitated vessel. And also how can we say this heat transfer area for all, because we may have internal coil or limpet coil or simple jacket at that time also do we have same area. Estimate the reactor volume, conversion coolant flow rate at a time when 95 percent conversion is attained. The vessel is well mixed, so the bulk temperature inside the reactor is about the same as the temperature flowing out the exit stream.